New Gear Keeper® guide includes fully illustrated, 6-page section on how to tether seemingly un-tetherable tools.

Even small tools that are dropped from above are serious safety hazards. When working at heights, some of the most commonly used tools, that don’t have attachment points, are often improperly secured and need to be tethered. The new literature from Gear Keeper offers simple and convenient tethering solutions that will safely secure a tool while still retaining the benefit of extending and retracting the tool as needed.

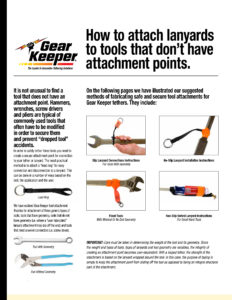

It is not unusual to find a tool that does not have an attachment point. Many commonly used tools often have to be modified in order to secure them and prevent “dropped tool” accidents. In order to safely tether these tools you need to create a secure attachment point for connection to your tether or lanyard. The most practical method is to attach a “load ring” for easy connection and disconnection to a lanyard. This can be done in a number of ways based on the tool, the application and the user.

It is not unusual to find a tool that does not have an attachment point. Many commonly used tools often have to be modified in order to secure them and prevent “dropped tool” accidents. In order to safely tether these tools you need to create a secure attachment point for connection to your tether or lanyard. The most practical method is to attach a “load ring” for easy connection and disconnection to a lanyard. This can be done in a number of ways based on the tool, the application and the user.

The illustrated “how to” reference is included in the company’s free new 16-page “Safety Engineer’s Guide to Tool Tethering.” The multi-page section titled “How to attach lanyards to tools that don’t have attachment points,” contains over 50 demonstration photos. They illustrate the guide’s tool attachment “how-to” theories such as Swivel Connection Tools, Slip vs. Non-Slip Connections and Attaching Tools With Minimal Geometry” in a step-by-step presentation. There is also a section covering non-slip, swivel connections for small hand tools that solves the problem of tethering commonly used tools such as screw drivers, pliers, hammers and others that lack the necessary geometry or don’t have built-in attachment points required for tethering.

Covered in the guide are workplace considerations such as; tethers for working in confined quarters or climbing; tethers that allow for quick interchangeability of tools and tethers designed to anchor a heavy tool to a structure instead of a person. Even tethers for other common workplace objects such as hard hats, security cards, cell phones and more are covered in the guide.

According to John Salentine, VP of Hammerhead Industries, “the new Safety Engineer’s Guide to Tool Tethering is the first document of its kind. It is a major step forward in helping safety engineers properly tether tools.” Salentine added, “This information will make every employee and their work site safer and more efficient.”

To get your copy of the the Guide, find a dealer near you or for more information about any of the company’s other innovative tethering products and accessories contact Customer Service, Hammerhead Industries Inc, 1501 Goodyear Avenue, Ste. C, Ventura, California. 93003 at (888) 588-9981 – gearkeeper.com.