Reduce Injuries, Damage & Lost Work Time.

Objects dropped from above were the fourth leading cause of industrial accidents and a $5.6 billion cost to industry.

A significant workplace safety issue is attracting quite a bit of attention: tools and other objects dropped when working at heights. Apart from the inconvenience of having to interrupt work in order to retrieve or replace a dropped tool, there is an extraordinarily serious risk of injury or damage. Think about this; a one-pound tool falling just 30 feet will hit the ground in less than 2 seconds.

Although a falling tool from any height is a problem, when it falls several hundred feet, equipment and personnel below are in considerable danger. The worker who dropped the tool endangers everything and everyone below him. It is a site safety issue. Even a screwdriver that hits someone after being dropped just ten feet is going to cause serious injury. A larger, free-falling tool, such as a cordless drill, could kill someone. That injured employee is going to cost his company money in lost productivity, workmen’s compensation claims, medical bills and, depending on the circumstances, the possibility of a lawsuit. Morale also becomes an issue anytime someone is injured on the job.

The threat of injury is not the only serious problem. Equipment and machinery can also be severely damaged, sometimes beyond repair, from a falling tool. At greater risk than others, certain industries such as nuclear power generation, wind power, aerospace manufacturing and oil and gas production are more prone to damage and injury. A relatively small wrench could cause severe damage to the fuselage or wings of an airplane as it bounces off the plane the whole way down. Whether it’s hitting something as expensive and sensitive as the skin of an airplane, or landing on a pump or bearing, a falling tool is going to create costly damage every time.

According to Liberty Mutual’s 2010 Safety Index1, accidents caused by falling objects cost U.S. industry $5.6 billion. A staggering figure, yet this type of accident is almost completely preventable by using an inexpensive tethering device. At present, OSHA Reg. #1926.759 (a)2 , which states that “equipment and tools, which are not in use while aloft, shall be secured against accidental displacement,” applies to the construction industry. But if we follow Europe’s example, as OSHA often does, it will soon be mandatory for all industries.

Working at height in itself is dangerous. Aside from the possibility of falling, the chance of being struck by dropped tools has proven to be a considerable risk. The “European Directives” set out minimum requirements and fundamental principles of prevention and risk assessment of objects falling from aloft, as well as the responsibilities of employers and employees. The regulations became effective with the 2005 introduction of ‘The Working at Height Regulations – specifically covered in Regulations 10 and 11 (Falling objects) which says:

• When it is necessary to prevent injury, you must do all that is reasonably practicable to prevent anything falling.

• If it’s not reasonably practicable, you must ensure that no one is injured by anything falling.

• You must ensure that nothing is: Thrown or tipped from height if it is likely to injure anyone. Stored in such a way that its movement is likely to injure.

• If the workplace contains an area in which there is a risk of someone being struck by a falling object or person, you must ensure that the area is clearly indicated and that as far as reasonably practicable unauthorized people are unable to reach it.

In the UK alone, falling objects was one of the primary causes of deaths and injuries in the work place. According to RIDDOR’s “ Health and Safety Executive 2008/2009” report, during the 12-month period from April 2008 to April 2009, the following fatalities and accidental injuries were caused by falling objects.

• 15 Deaths

• 3,223 Non fatal major accidents

• 11,981 Workers lost more than 3 days of work time

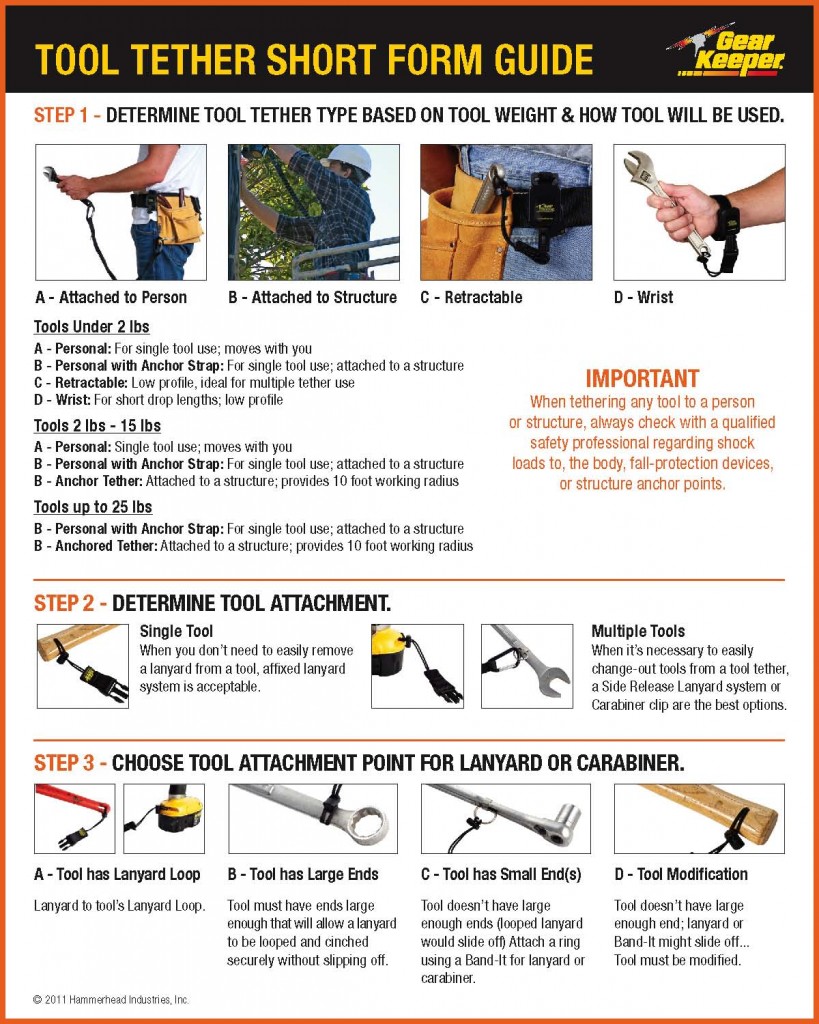

Most of these accidents could have been prevented. Personal tool tethers and lanyards are the most effective way to protect employees from objects falling from above. When the correct tether is properly matched with the tool, worker and application, the work is safer, easier and more efficient. Employees will appreciate always having their tools and instruments conveniently at hand when they need them and out of the way when they don’t. Conversely a poorly matched tether can actually become a safety hazard. The challenge to the safety engineer is to provide a tether that is both friendly to the user and appropriate for the work environment.

The common lanyard-type tool tether is not a one-size-fits-all solution.With such a high risk to workers’ safety, it’s unfortunate that very little has been published on the subject of tethering equipment and tethering safety techniques. Many safety professionals may not be aware of the range of options available to them. Most companies that sell safety equipment or personal fall arrest systems fill out their product line by importing a basic tether in two or three sizes. When tool tethers are ordered without specifications beyond the weight of the tool, chances are good that the tether may not be appropriate.

In reality, there are thousands of tethering choices for safety engineers available from U.S. manufacturers specializing in tool, gear and instrument tethers. Systems that have been specified by safety engineers for a variety of tethering applications in a broad range of industries including wind energy, fire and rescue, manufacturing, law enforcement, military, trucking, oil and gas exploration, SCUBA, fishing, and communications. Each application has its own set of criteria; standing up to saltwater, chlorine exposure and high temperatures, or special mounting or attachment needs. Manufacturers like Hammerhead Industries, Inc. (gearkeeper.com) and Snap-on Tool’s (snapon.com ) “Tools at Height program,” are addressing the problem.

Tethering Safety: Use the appropriate lanyards and tethers for each application.

Obviously the objective of tethering is to secure tools to prevent injury and damage to people and equipment below… but there are factors that may impact the safety of the worker using the tether or lanyard. An improperly mated tool and lanyard can inherently lead to reduced productivity and exposure to injury. When the tethering device limits mobility, recoils too fast or exerts too much resistance upon extension, backlash from workers is often the result. Generally the result is fatigue, annoyance and often non-compliance in the use of the lanyard.

Tethers of that type use an elastic core placed inside tubular webbing and provide minimal stretch/recoil. The heavy elastic may add a “shock-absorbing” factor to a heavy dropped tool but conversely, because of its high stretch strength, the worker’s muscles will tire quickly when he extends to full reach. If the tethered tool is fairly light, the “shock-absorbing” elastic will actually cause the tool to “slingshot” back to the user too swiftly. It may actually injure or unbalance the worker. In either situation, improperly mated tools and lanyards may force safety engineers to deal with non-compliance, potential injury and reduced worker output.

The correct manufacturing philosophy is to provide a lanyard that has very low stretch force so as not to fatigue the user at full extension, while providing the proper degree of recoil. This is achieved by having the elastic material sewn inside the webbing during the manufacturing process and not assembled after the fact. In this manner, the elastic provides optimum retraction tension and low force stretch. This becomes clear when you compare a typical “Tubular Webbing Lanyard” to a typical “Gear Keeper Lanyard.” Consider the following specifications:

Typical Imported Elastic Core / Tubular Webbing lanyard

Retracted length = 36”

Extended length = 44”

Strength length = 8”

Extended force (approximately 2 lbs)

Stiffness factor (scale of 1 – 10): 7.5

Typical Gear Keeper Personal Tool Tether (3/4” super coil)

Retracted length = 31”

Extended length = 46”

Stretch length = 15”

Extended force (approximately .75 lbs)

Stiffness factor (scale of 1 – 10): 3.5

For heavier tools, tethers should be anchored to a structure not a person.

Tethering heavy tools, (generally over 5 pounds) to a person is a significant safety concern and safety engineers should instead consider using anchor tethers. Anchored tethering transfers the shock load produced by a dropped tool from the worker to the structure. For very heavy tools (over 10 pounds), structure anchoring should be mandatory.

In addition to the obvious protection of transferring the shock load, the anchored tether also minimizes entanglement issues but because of the longer reach, other concerns need to be considered. The tether must have a higher stretch capability, otherwise it will coil up or cause stress to the worker. It also needs to have a higher break strength since the drop distance of the tool (as a result of the longer reach), will produce higher shock loads at the stop point. A unique manufacturing process resulting from our experience in the SCUBA industry has solved that problem. A polyurethane coil is employed inside of the tubular webbing giving the worker an extremely long stretching ability, using virtually no force. The result is the creation of a large working radius (up to 10 feet). Typical specifications for this type of tether are:

Anchored Tether – 1” Super Coil

Retracted Length = 40”

Extended Length = 124” (9’ – 10’) working radius from the attachment point

Stretch length = 84”

Extended force (approximately .75 lbs)

Stiffness factor: 4

Retractable Tethers for workers using small hand tools less than 2 pounds.

Picture the worker using multiple small tools… the electrician using screw drivers, pliers, amp meters… or a scaffold builder climbing up with a group of tools in his pouch… these tools and working conditions are poor choices for coil type tethers or lanyards. But they are ideal for a retractable tether that safely permits multiple tools to be attached to the worker with virtually no risk of entanglement or snagging. Tool and gear retractable tethering devices offer hundred’s of combinations of mounting systems, line technology and shock absorbing capabilities. This type of highly engineered safety tether provides cost effective security along with very high tool ratings.

Quick-Release fittings for multiple tools on one tether.

Change the tool not the tether. A single tool lanyard is sufficient when one specific tool is the only thing tethered, but what do you do when you have multiple tools to tether? It’s a very common scenario in most industries. Here again there are many options for worker safety in multi-tool tethering situations. Quick Connect tethers offer easy tool change-out and are available on a large selection of tethers.

Tool Tether Ratings

Tool tether ratings have not been established or standardized by either the tethering or the safety industry. There are no universal specifications governing tool tethers as there are with fall protection devices. As such, the safety engineer, when specifying a tool lanyard, has no real basis for choosing proper tethers and arbitrarily determines tether selection based on the weight of the tool, i.e. “I need a tether for a 3 lb tool.” Without additional specifications, the safety engineer maybe creating a potentially dangerous situation.

Even though the industry is lagging behind in establishing guidelines, my experience has shown that for maximum safety, tool tethers and lanyards should meet a 25% margin for a full extension drop. However a more significant concern is how some suppliers arbitrarily rate their lanyards just so it meets a customer’s request. As an example, when a safety engineer request a tether for a 3 lb tool, the distributor may say, “I’ll send you one for that’s rated up to 15 lbs, so you have a higher safety margin.”

Although both the supplier and the buyer may have good intent, this is a potentially hazardous situation for a couple of reasons. One, using a tether that is rated for a much heavier tool will not operate effectively because the stretch and the recoil are considerably out of scale for the lighter tool. An additional and more serious problem is when a worker, assuming a lanyard is rated for 15 lbs, thinks he can connect a 15 lb tool to his tool belt. He can’t. That 15 lb tool, at a full drop length, will exceed 250 lbs of a shock load. More than enough to knock a worker off his perch. What if a personal fall protection device does not further protect that person?

I strongly advocate that safety engineers explore practical tool tethering solutions with reputable manufacturers. A lanyard that is rated for the weight of the tool is safe to use. When a tool that weighs 5 to 10 lbs is attached to a person, an appropriate safety professional should always approve it. Above 10 lbs, the tool should always be secured to a proper structure.

Lastly, if anchored tethers are used, the anchor point should also be approved by a qualified safety professional. Many times, a lifeline rated for personal fall protection can also be used, but again the appropriate safety person should approve this as well.

Make the employee your partner in tethering.

For your tool and instrument tethering safety program to be successful, a partnership must exist between the employee and the safety engineer. A properly tethered tool or instrument makes work more efficient. It simplifies every repair, maintenance or manufacturing project by keeping the workers’ tools handy and accessible. When tethers correctly complement the tool, worker and application, you will have an advocate rather that an antagonist.

In conclusion

The safety engineer’s goal in correct tethering procedures is to make sure the tool, application and recoil/retraction force are in balance. When the tool is extended for use, only minimal force should be necessary so as not to cause worker fatigue or in the reverse, cause a ”kick” when retracted. The result of correct tethering is when the tool is stored, held or used, the dangers of entanglement, fatigue and annoyance are minimized and worker satisfaction and output are maximized. Tethering manufacturers, like those previously mentioned, focus on being solutions providers, working with customers who are trying to put together a tool tethering safety program that adequately protects their employees without inhibiting their work demands. airmaxgeschaft airmaxgeschaft